Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

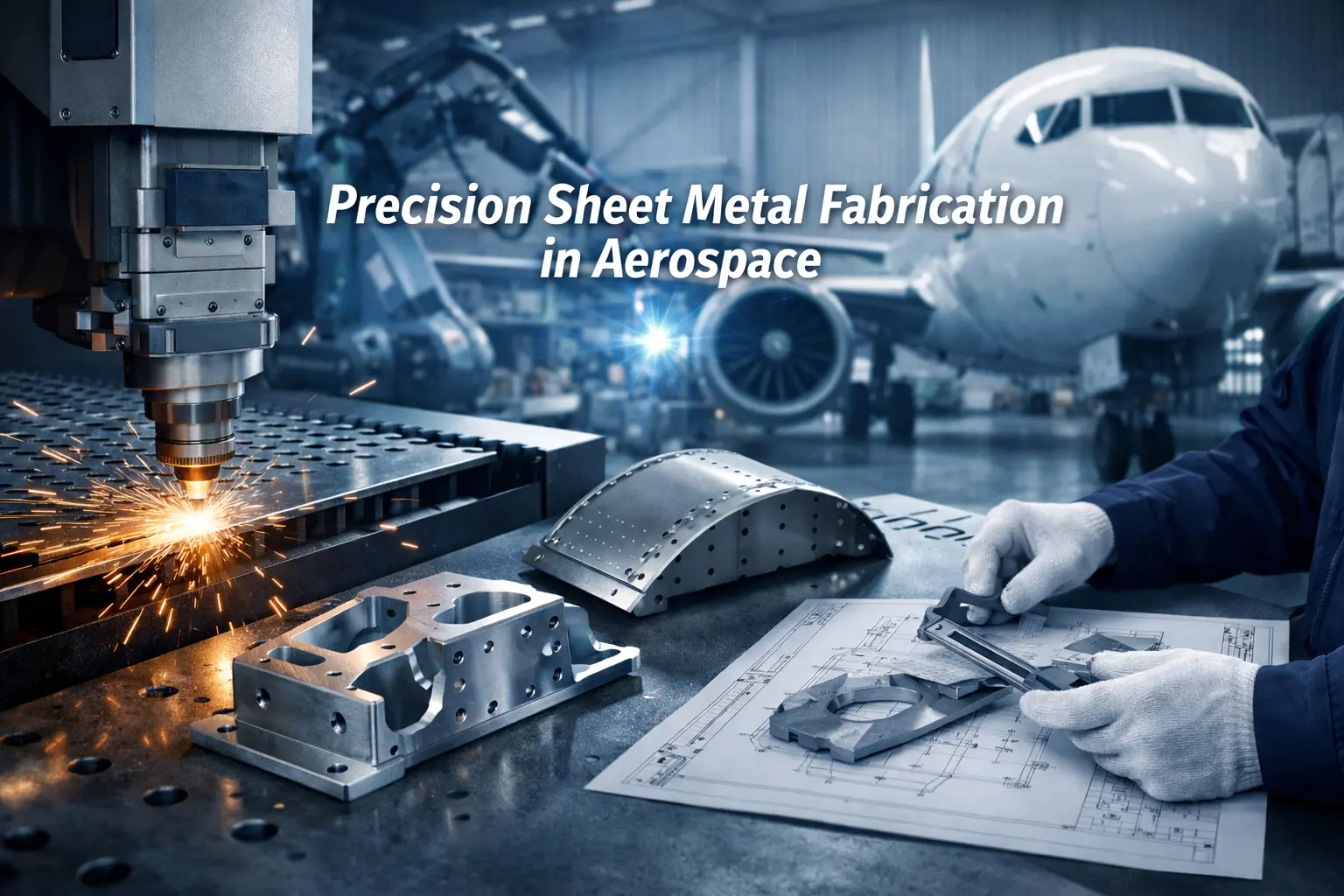

Aerospace engineering thrives on innovation and precision, where even the smallest deviation can have significant consequences. From commercial aircraft to advanced spacecraft, every component must meet exceptionally high standards for accuracy, strength, and reliability. Within this demanding environment, sheet metal fabrication stands out as a critical manufacturing discipline that directly supports performance, safety, and efficiency.

Advanced sheet metal fabrication processes embody the innovative spirit of the aerospace industry. Through techniques such as precision cutting, forming, bending, and joining, engineers are able to create lightweight yet robust components that withstand extreme temperatures, pressure variations, and mechanical stress. As aerospace designs continue to evolve—becoming more complex, lightweight, and performance-driven—these fabrication processes are constantly refined to push the boundaries of what aircraft and spacecraft can achieve.

In this blog post, we will examine the vital role of sheet metal fabrication in the aerospace industry and explain why it is far more than a supporting process. From structural components and enclosures to aerodynamic panels and critical assemblies, sheet metal fabrication serves as a fundamental pillar of modern aviation and space exploration, enabling innovation while ensuring compliance with stringent industry standards.

Precision is not optional in aerospace manufacturing—it is fundamental. Sheet metal components are often used in load-bearing structures, aerodynamic surfaces, and protective enclosures, where even minor deviations can affect performance or safety. Precision sheet metal fabrication ensures that each part meets exact specifications and performs reliably throughout its service life. Its importance can be understood from several key perspectives.

Structural Integrity

Aerospace structures are designed to endure constant stress, vibration, and extreme environmental conditions. Precision sheet metal fabrication ensures consistent material thickness, accurate bends, and tight tolerances, all of which contribute to structural stability. When parts fit together exactly as intended, stress is distributed evenly, reducing the risk of fatigue cracks, deformation, or premature failure over time.

Weight Optimization

Weight reduction is a constant priority in aerospace design, as even small weight savings can translate into significant fuel efficiency and performance gains. Precision fabrication allows engineers to use thinner materials and complex geometries without compromising strength. By removing unnecessary material while maintaining structural integrity, manufacturers can achieve optimal strength-to-weight ratios that are critical for both aircraft and spacecraft.

Aerodynamic Performance

Aerodynamic efficiency depends heavily on surface accuracy and consistency. Precision sheet metal fabrication helps maintain smooth contours, tight seams, and accurate alignment between panels. These details directly influence airflow behavior, drag reduction, and overall flight performance. Poorly fabricated or misaligned components can disrupt airflow, increasing resistance and reducing efficiency.

Safety and Reliability

In aerospace applications, safety margins are extremely tight. Precision fabrication reduces variability between parts, ensuring predictable performance under operating conditions. Consistent quality also minimizes the risk of assembly issues, unexpected stress concentrations, or in-service failures. This level of reliability is essential for meeting the long service life and safety expectations of aerospace systems.

Customization and Design Complexity

Modern aerospace projects often involve highly customized components and complex designs. Precision sheet metal fabrication makes it possible to produce low-volume, high-complexity parts with repeatable accuracy. Advanced forming and cutting techniques allow manufacturers to meet unique design requirements without sacrificing quality, supporting innovation in both commercial and defense aerospace programs.

Regulatory Compliance

The aerospace industry operates under strict regulatory frameworks, with rigorous requirements for traceability, dimensional accuracy, and process control. Precision sheet metal fabrication supports compliance by ensuring parts consistently meet design specifications and quality standards. Accurate fabrication also simplifies inspection, documentation, and certification, which are essential for regulatory approval and long-term program success.

Sheet metal fabrication plays a central role in aerospace manufacturing, supporting the production of structural components, enclosures, brackets, panels, and complex assemblies. While aerospace applications demand exceptionally high standards, many of the services used are established fabrication processes that have been refined to meet strict industry requirements. Below are the standard sheet metal fabrication services commonly applied in aerospace manufacturing.

Precision cutting is the foundation of all sheet metal fabrication work. In aerospace manufacturing, laser cutting, waterjet cutting, and CNC punching are widely used to achieve clean edges and tight dimensional tolerances. These methods allow manufacturers to process aluminum alloys, stainless steel, titanium, and other aerospace-grade materials with minimal distortion, ensuring consistency from part to part.

Forming and bending operations shape flat sheet metal into functional components while maintaining material strength. Press brakes, roll forming, and stretch forming are commonly used to create brackets, frames, and structural elements. Precise control of bend angles and radii is essential, as inaccuracies can affect fit, load distribution, and assembly alignment.

Stamping processes are often used for high-repeat components that require consistent geometry. Progressive and compound dies enable efficient production of parts such as clips, reinforcements, and mounting features. In aerospace applications, stamping operations are carefully controlled to avoid material thinning or stress concentrations that could compromise performance.

Joining processes are critical for assembling sheet metal components into larger structures. Aerospace sheet metal fabrication commonly involves TIG welding, resistance spot welding, and riveting. These methods are selected based on material type, joint design, and structural requirements. Proper weld quality and joint integrity are essential to ensure long-term durability under vibration and cyclic loading.

Many sheet metal parts require secondary machining operations, such as drilling, tapping, countersinking, or slotting. CNC machining ensures hole placement accuracy and proper interface with fasteners or mating components. Deburring and edge finishing are also important to prevent stress risers and improve part safety and handling.

Surface treatments are applied to improve corrosion resistance, wear performance, and appearance. Common finishes in aerospace sheet metal fabrication include anodizing, chemical conversion coatings, passivation, and painting. These treatments help protect components in harsh operating environments while meeting both functional and regulatory requirements.

Quality control is an integral part of aerospace sheet metal fabrication. Dimensional inspections, visual checks, and material traceability are routinely performed to ensure compliance with specifications. Accurate documentation and consistent inspection processes support regulatory compliance and provide confidence in part performance throughout its service life.

Material selection is a critical decision in aerospace sheet metal fabrication. Components must meet strict requirements for strength, weight, corrosion resistance, and performance under extreme conditions. The materials used in aerospace manufacturing are chosen not only for their mechanical properties but also for their reliability, consistency, and long-term durability. Below are the most common sheet metal materials used in aerospace applications.

Aluminum alloys are among the most widely used materials in aerospace sheet metal fabrication. They offer an excellent balance of strength, low weight, and corrosion resistance, making them ideal for structural panels, frames, brackets, and enclosures. Grades such as 2024, 6061, and 7075 are commonly selected depending on strength requirements and forming characteristics. Aluminum is also highly machinable and compatible with surface treatments like anodizing and chemical conversion coatings.

Titanium alloys are used in aerospace applications where high strength, low weight, and temperature resistance are required. Although more difficult to fabricate than aluminum, titanium offers exceptional corrosion resistance and maintains its mechanical properties at elevated temperatures. It is often used in engine-related components, structural reinforcements, and areas exposed to harsh environments where durability is critical.

Stainless steel is valued in aerospace sheet metal fabrication for its strength, heat resistance, and corrosion performance. It is commonly used for components subjected to high stress, wear, or temperature fluctuations, such as brackets, fasteners, and exhaust-related parts. While heavier than aluminum and titanium, stainless steel provides excellent reliability and long service life in demanding conditions.

Nickel-based alloys, such as Inconel, are used in aerospace applications that require extreme heat and oxidation resistance. These materials retain strength at high temperatures and are often found in engine components, heat shields, and exhaust systems. Although challenging to form and machine, nickel alloys are essential for applications where standard metals cannot meet performance requirements.

Magnesium alloys are sometimes used when weight reduction is a primary concern. They are significantly lighter than aluminum but offer lower strength and corrosion resistance. As a result, magnesium is typically limited to non-critical components or interior structures where weight savings outweigh other considerations. Proper surface protection is essential when using magnesium in aerospace applications.

In addition to standard alloys, aerospace manufacturers may use specialty or hybrid materials designed for specific performance requirements. These include clad materials, high-strength aluminum-lithium alloys, and customized alloy compositions. Such materials are often selected to optimize weight, fatigue resistance, or environmental performance for specialized aerospace programs.

Selecting the right sheet metal material is a critical step in aerospace manufacturing. The choice directly affects part performance, reliability, cost, and long-term service life. Rather than relying on a single factor, aerospace material selection typically involves balancing mechanical requirements, environmental conditions, manufacturability, and regulatory constraints.

The first step is to clearly understand how the part will function within the overall system. Load-bearing components require materials with sufficient strength and fatigue resistance, while non-structural parts may prioritize weight or formability. Factors such as tensile strength, stiffness, and resistance to vibration should be evaluated early in the design process to avoid costly redesigns later.

Weight plays a major role in aerospace performance and operating efficiency. Lighter materials can reduce fuel consumption and improve payload capacity, but they must still meet strength and durability requirements. Aluminum and magnesium alloys are often selected for weight-sensitive components, while titanium or stainless steel may be necessary where higher strength or temperature resistance is required.

Aerospace components are often exposed to extreme temperatures, pressure changes, moisture, and corrosive environments. Materials must maintain their properties under these conditions throughout the part’s service life. For example, titanium and nickel-based alloys perform well at elevated temperatures, while aluminum alloys with proper surface treatment offer good corrosion resistance in many applications.

Not all materials behave the same during cutting, bending, or forming. Some high-strength alloys require specialized tooling or tighter process control, which can impact lead time and cost. Understanding how a material responds to fabrication processes helps ensure consistent quality and reduces the risk of cracking, distortion, or excessive scrap during production.

Material cost and availability should be evaluated alongside performance requirements. While premium alloys may offer superior properties, they may not be practical for high-volume production or cost-sensitive programs. In many cases, standard aerospace-grade aluminum or stainless steel provides a more balanced solution without compromising reliability.

Regulatory compliance is a non-negotiable factor in aerospace manufacturing. Materials must meet industry standards and customer specifications, often requiring full traceability and certification. Choosing materials that are widely accepted and well-documented can simplify qualification, inspection, and approval processes.

Early collaboration between design engineers and fabrication specialists can significantly improve material selection decisions. Manufacturers can provide valuable insight into material behavior, process limitations, and cost implications, helping to align design intent with practical production considerations.

Is the part structural or non-structural?

Load-bearing parts require higher strength and fatigue resistance, while secondary components may prioritize weight or formability.

What are the operating conditions?

Consider temperature range, vibration, humidity, corrosion exposure, and pressure changes.

How critical is weight reduction?

Weight-sensitive components may justify higher material costs if performance gains are significant.

Can the material be fabricated consistently?

Evaluate how the material behaves during cutting, bending, welding, and forming.

Does the material meet aerospace standards and certifications?

Ensure traceability, material specs, and compliance requirements can be met.

Is the cost aligned with production volume and program budget?

Avoid overengineering when standard aerospace-grade materials are sufficient.

Finishing and post-processing are critical steps in aerospace sheet metal fabrication. Beyond shaping and assembling components, these processes enhance durability, performance, and compliance with strict aerospace standards. Proper finishing not only improves corrosion resistance and wear performance but also ensures that components meet functional and aesthetic requirements.

Anodizing is widely applied to aluminum sheet metal components. It creates a protective oxide layer that improves corrosion resistance, surface hardness, and wear properties. Additionally, anodizing can be dyed in different colors for part identification or aesthetic purposes. This process is especially valuable in structural panels, frames, and exterior surfaces exposed to harsh environments.

Chemical conversion coatings, such as Alodine or chromate treatments, provide thin protective layers on aluminum and other alloys. They enhance adhesion for subsequent painting or sealing processes and improve corrosion resistance. These coatings are commonly used for parts that require both environmental protection and paint adhesion, such as interior panels, brackets, or assemblies in sensitive areas.

Passivation is a standard post-processing treatment for stainless steel components. It removes free iron from the surface and promotes the formation of a corrosion-resistant oxide layer. This process is crucial for aerospace parts exposed to moisture or corrosive agents, including brackets, fasteners, and engine-adjacent components.

Painting and powder coating provide additional protection and improve the visual appearance of aerospace components. Powder coating offers a uniform, durable layer with resistance to chipping and wear, while liquid painting allows more complex color matching or custom finishes. Both techniques are used to protect interior and exterior parts, improve inspection visibility, and prevent surface degradation over time.

Mechanical finishing processes such as deburring, grinding, polishing, and shot peening help achieve smooth edges, remove sharp burrs, and relieve residual stresses. These processes are essential for structural integrity, assembly fit, and fatigue resistance. For high-performance aerospace components, precision mechanical finishing ensures consistent performance and reduces the risk of stress concentration points.

Finishing and post-processing are incomplete without rigorous quality control. Visual inspections, coating thickness measurements, adhesion tests, and corrosion resistance checks are performed to ensure compliance with aerospace standards. Proper documentation and traceability are maintained to meet regulatory requirements and guarantee long-term reliability.

Quality assurance (QA) is a cornerstone of aerospace manufacturing. In an industry where safety, reliability, and regulatory compliance are non-negotiable, rigorous QA processes ensure that every component performs as intended throughout its service life. From raw material inspection to final assembly, QA practices are integrated at every stage of the manufacturing process.

The foundation of quality assurance begins with material verification. Aerospace materials, including aluminum, titanium, stainless steel, and specialty alloys, must meet strict specifications for composition, strength, and traceability. Each batch is tested and documented to confirm it aligns with required standards, ensuring that no substandard material enters production.

Precision is critical in aerospace manufacturing. Dimensional inspections are conducted at multiple stages to ensure components meet design tolerances. Techniques include coordinate measuring machines (CMM), laser scanning, and optical measurement systems. Accurate dimensions are essential for proper assembly, structural integrity, and aerodynamic performance.

Non-destructive testing methods, such as ultrasonic testing, X-ray inspection, dye penetrant, and eddy current testing, are used to detect internal or surface defects without damaging components. NDT is particularly important for load-bearing parts, engine components, and critical assemblies where failure could compromise safety.

Aerospace QA also emphasizes controlled processes and thorough documentation. Standard operating procedures, work instructions, and process audits ensure repeatable quality across all manufacturing stages. Detailed records, including inspection reports and certifications, support regulatory compliance and provide traceability for each component.

Before components leave the manufacturing facility, they undergo assembly verification and final inspection. Fit, alignment, surface quality, and functionality are checked to ensure that each part meets performance expectations. Any deviations are corrected before delivery to maintain the highest standards of safety and reliability.

Quality assurance in aerospace is not static; it is an ongoing commitment. Data from inspections, testing, and field performance are analyzed to identify trends and opportunities for improvement. This continuous feedback loop allows manufacturers to refine processes, reduce defects, and enhance overall product quality.

Aerospace manufacturing demands unmatched precision, reliability, and adherence to strict industry standards. At WEYOUNG CNC, we specialize in delivering high-quality sheet metal fabrication and precision machining services tailored for aerospace projects of any scale. Partnering with us ensures your components meet exact specifications, comply with regulatory requirements, and perform reliably in the most demanding environments.

With years of experience serving aerospace clients worldwide, WEYOUNG CNC has developed deep expertise in materials, tolerances, and fabrication processes. From aluminum and titanium alloys to stainless steel and specialty metals, our team understands the unique challenges of aerospace applications and delivers solutions that meet both performance and regulatory standards.

Our state-of-the-art CNC machines allow for highly precise cutting, forming, and machining of complex components. Tight tolerances and repeatable accuracy are critical in aerospace projects, and our equipment ensures every part matches design requirements consistently.

WEYOUNG CNC offers a full range of sheet metal fabrication services, including cutting, bending, stamping, welding, post-processing, and finishing. We also provide secondary operations, such as drilling, tapping, and surface treatments, ensuring that your components are ready for assembly or integration.

Quality assurance is central to every project. We maintain rigorous inspection processes, non-destructive testing, and full documentation to guarantee compliance with aerospace standards. Every part is traceable and verified, giving you confidence in performance, safety, and reliability.

No two aerospace projects are exactly alike. WEYOUNG CNC has the flexibility and technical expertise to handle custom designs, low-volume production, and complex geometries. We work closely with clients from the design stage to production, providing guidance on material selection, manufacturability, and finishing options.

We understand the importance of schedules in aerospace projects. Our streamlined production processes, efficient workflow management, and proactive communication ensure that your components are delivered on time, every time.

Partnering with WEYOUNG CNC means combining precision engineering, advanced manufacturing capabilities, and a commitment to quality—all designed to bring your aerospace projects to life safely and efficiently.